indiefilm

Members-

Posts

69 -

Joined

-

Last visited

Content Type

Forums

Gallery

Store

Everything posted by indiefilm

-

I can’t speak to any previous, discontinued models, but if weight was of no concern to me I too might consider other brands than PENN Elcom. I have installed two of their 18” inch PENN-Elcom 4U drawers in the last two months from different orders a month or so apart and found no flaws in the alignment or construction. Same with three or four of their laptop drawers several months ago and their sliding shelf which seems limited on payload ability but how heavy can the average mixer be, but their shelves seem well made and string relative to their weight. The glides they probably buy from someone else and they were quite responsive when I told them the glides have a design flaw that prevents them from being as strong as they could easily be, but the 4u drawer easily held the weight it was rated for, 75lbs, while glides were fully extended. I simply tested it till destruction on purpose and that was 150lbs on unlevel ground fully extended so the load was probably way more than half that on the downhill glide that failed. As for their service, frankly during Covid 19 I have been greatly disappointed by the level of service that most companies I interact with are giving as they are using COVID-19 as an excuse but whenever I call my contact at penn elcom he almost always answers the phone himself immediately and is very attentive and follows through on promises pretty well. He asked me to send him photographs of the failed glide and said he would forward them to the engineering department along with my recommendation as to how they can improve them. And of course in order to compare apples with oranges one has to take into consideration the weight of the drawer as well and I have found that PENN Elcom is good about having products that don’t weigh a lot relative to their strength. I ordered some other brands of steel Rackmount shelves through Amazon that were way way way too heavy so I sent them back. If I do find any other weak points in their steel drawer design after I get some beefier drawer glides I’m fairly certain I can cheaply and easily eliminate that by tastefully reinforcing it if and where necessary. They were even willing, with the relatively inexpensive Uncharge of 30%, modify some of their products for me with a relatively modest order quantity in my opinion But at this point I haven’t decided if I’m going to take them up on that. I am looking forward to the arrival of the six special ordered 4u 18” aluminum drawers that I ordered so I can perhaps test one of them till failure. I was especially happy that they offer their drawers in the 18 inch deep size, Unlike many other manufacturers. Obviously the deeper The Drawer the more stress on the glides when you open it fully, under load.

-

I tested an 18” x 4U PENN-Elcom steel drawer till destruction with it all the way open. Took about 150 lbs. of static load before failure. I didn’t have the rear of it attached yet, but it was the drawer glide that failed on these drawers so did not matter. These glides are strangely designed in a way that unnecessarily reduces their strength right where the three rivets attach them to the sides of the outer shell. Drawer was only rated for 75# And I assume that is a static load rating. if you solve the problem that causes these glides to be the weak link I too suspect that having the rear of these drawers attached would increase their strength. I have some of their 4U aluminum drawers on order. They don't stock them and unless you want to pay for air freight they are special order and take 3 months as they must get a full container of stuff ready first and send across by boat from the UK to LA. They sell some stand alone heavy duty 18” glides rated at 130#s. I assume that rating is also a static load rating . I don’t know if you can special order their drawers, steel or aluminum, with these heavier duty glides already installed or not but you could always Grind the rivets off of their drawer glides, remove them and Rivet on some of your own or their heavier duty ones if they won’t install them for you when they make it. They make a small bracket for attaching the rear of the drawers to a back set of rack rail but you can make your own thing for that too. I’m sure their bracket is adjustable for varying depths of frame which of course will make it a little heavier and a lot longer which you may not need or want. When I receive them in a month or two I may static test one of the aluminum drawers to failure since I plan on replacing the glides anyway And if there is interest I will post the results here. My static test may involve a little movement of the cart but since I can’t measure G forces there’s no point in doing a real dynamic test. Which brand and size were you planning on using and what load are they rated at may I ask?

-

They told me they are swamped making guards to separate people for Covid. Glad, so far, my design does not required any CNCing

-

Curious how your cart turned out? Any pics yet?

-

So what are we looking at here. Is the panel with the Lectrosonics in it less than 1.75” wide? If so, is it a custom made panel?

-

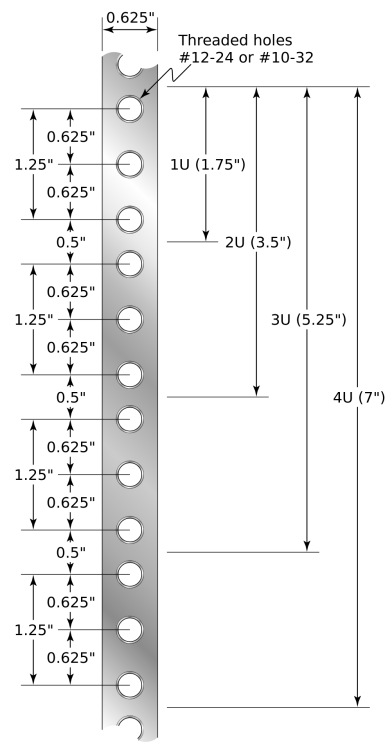

Looking at this drawing how would that work? How could you leave just part of a RU vacant for ventilation by utilizing the center hole? Not seeing it Looks like those will all fit in a standard, 19” slide out shelf

-

PS Can someone tell me the purpose of the center hole in each RU on rack rail?

-

Did you get my email?

-

I am finalizing my design for a head turning, extremely versatile location sound mixer cart I will be selling soon. Would like to know the 3-5 most popular mixer models and brands people are using so I can obtain their dimensions to make sure they will fit horizontally and how much vertical space they require. Any help much appreciated. Mark Pope Stabilitech®

-

Thanks for your email. I will email you. Always looking for more input on the various features people want. This cart is unlike any other and more flexible as to setup than anything on the market, otherwise why bother.

-

Derek, The black anodizing is relatively durable in my opinion. I will soon be selling a very amazing and versatile 80/20 based cart I have been refining for over 3 years. I have a B.S. degree in architecture and 3 years experience working as a structural engineer for Skidmore. Owings & Merrill, designers of Sears Tower in Chicago. I have been involved in audio/video production since 2009. I assume you are using 15 series in order to be able to use those connectors? i know 80/20 is pretty expensive with their milling charges. Their connectors are very expensive too so I designed some of my own I believe are patentable which I will soon file for a patent on. Mine are easy to install and at a minimum are twice as strong. Are you using any rack mount gear? Are you wanting to be able to check as baggage with an airline?

-

Shut down until all can be tested

-

Yes, that’s what I anticipated from having moved refrigerator sized furniture up/down stairs with too short a dolly vs with tall dolly. I plan on having best of both worlds.

-

Thx David for the closeups. I think I know what’s happening. Looks like rectangular or square bar in the t-slot for drawer glide. I am doing something kinda similar in places. Steel drawer glides are heavy, for sure, so using very few of them. What did he charge, roughly, for carts like this and how many could he make in a year?

-

Good to know since I may not be able to get larger ones. I think the ones I have are Arri and they can’t be much more than an inch in diameter. Funny, the OCD in me is designing this cart to be single handedly amenable to going up a flight of stairs fully loaded. Maybe even multiple flights, depending on your stamina. Wasn’t sure if there was a need but apparently there is.

-

Thx David. I am learning things overall from the discourse with everyone, often in ways nobody would guess, but grateful nonetheless. As I wrote before, I wish I could see one of these carts in person as the thing I would be most like to benefit from would be close-up details not clear from photos or the video that might actually spur use in a different way. Disadvantage to this type of monitor mounting solution seems to me to be you can’t easily change the height location. Also, I am bucking the current manufacturing trend here, but it looks like it requires a lot of machining. Necessity is the mother of invention. I don’t plan on getting my own CNC machine and besides, for cost and environmental reasons, I am trying to avoid turning 40-50% of the 6061 aluminum I just purchased for 5-10$ US per pound into shavings worth 10-30 cents per pound that require energy to be consumed/pollution to recycle them into a useable form of aluminum again. looks like he also did what possibly every other aluminum cart maker is doing today by bending flat sheet to make the shelves. Not to pick on this amazing, over the top cart, but since it is no longer s available for purchase hopefully everyone will forgive me for using it as the example. With its yield strength of 40,000 psi, 6061 alloy aluminum is much harder to permanently deform than 5052 with its yield strength of only 28000 psi. But 6061 is too brittle to bend, so they have to resort to using the weaker 5052 aluminum sheet for making bent shelves/work surfaces. 5052 is fine in some situations. No need and wasteful to reinvent the wheel, or the nuts and bolts, when and if I can find an existing though obscure part that can be creatively used. It’s not easy and is harder than ever to get a patent, must be “non-obvious to a (fictitious) person skilled in the art” but if anyone thinks a design using little or no custom parts is not patentable, think again. Somewhere on this forum I saw someone belittling carts using “off the shelf parts”. The most valuable company in the world today started out using a bunch of off the shelf parts. It requires more creativity to come up with a great design without milling machines, hence why so many resort to CNC these days, often with questionable results. Steve Wozniak refered to chips as “the lumber of the computer industry”. Architects design amazing, one of a kind buildings from homes to skyscrapers using off-the-shelf lumber, steel studs, joists, beams and columns. CNC has its uses. I will have some custom machined parts but hopefully few, and patentable. There may be exceptions but I am trying to make the designs as environmentally sustainable as possible while not cost prohibitive. Luckily the two often are not mutually exclusive.

-

Sure, I have plenty lying around I got from China when the FS7 first came out to fix the too short arm situation. But Those are only about 1” diameter which doesn’t give them much leverage/increases the stress on them. I am hoping to get some rosettes at least 1-1/2” - 2” in diameter. Anybody know of any that size?

-

The reason for the thicker frame was to provide a better/easier means for protecting the screen and or the rear connection. I had misspoke and written 3RU but it was really 3”/less than 2RU. I’ll work on a 1RU solution that protects the screen. Jeff, from my research so far, as you all probably already knew if I am correct, at least some of the other brands like the Lilliput have the same mounting and overall dimensions. Please correct me if I am wrong. I am still researching brands. Someone had mentioned one that is tiltable already, I believe, that I need to find the mention of research.

-

Thx Ollie. I’ll see what I can do to accommodate these ideas. As for detachable sections, there are several on the market that basically split horizontally/vertically into two sections. Is that what you had in mind or were you thinking of something more specific or different?

-

Thx Nate. Yes, Rosettes are great for that. Did they come with cart? If not can I ask where you got them and the name/model number?

-

So I am curious why you didn’t just tilt your cart back on the large, rear wheels when moving outside on a cracked footpath. Was it that the handle(s) on the cart was(were) not at a comfort table height/angle to do so?

-

That won’t be a problem with my carts or accessories. Designed not to break but if they do, parts are replaceable at the smallest of levels and obsolescence of the carts overall is out because of the extreme customizability of the designs... Obsolescence Made Obsolete™

-

literally slide into just 1 rack space? or would more be ok, like 3 or 4RU (if including room for say the Speakeasy speaker RU or a patch bay? It presume it could course slide into the back rackmount behind other, short-depth rack mount gear. Reason for deeper frame include better protection for from and or back of monitor and or attaching accessories.

-

Nate, Thx for feedback. Forgive me if I ask a stupid question as I am more a videocamera guy than a location audio guy. Would it be best if I provide the option of a small patch panel, possibly quick releasable, directly on my proposed tiltable frame for the Blackmagic Smartview Duo rackmount monitor? The Rastorder type cart design you mention requires everything be removed from the shelves to fold it up, so you are right, my carts design type is not leaning that way at this point. That seems to me to be an unnecessary requirement for a vertical cart, and though thinner when folded, it also becomes much longer and their small casters don’t quick release, do they? Is having to remove all the gear something That bothers you? It also is a very fragile design sure to get bent when folded if you ever check it as baggage, even if stored in their expensive soft bag. BTW, i have read other comments on this forum where people say they want very large front casters on the front of their cart, like 5-8”. I don’t understand why since if using the cart outside on unlevel and bumpy ground, where I presume they feel the need for the larger caster wheels, they would have plenty of room to tilt back the vertical cart to its huge rear wheels and move it like a two wheeled hand truck. Have you regretted that your Rastorder cart does not have bulkier, heavier 5 or 8” front casters?

-

That listing is no longer available.

.png.279748a58a2b862b7aa5f3b84126e232.png)