-

Posts

1,458 -

Joined

-

Last visited

-

Days Won

19

About David Waelder

- Birthday January 1

Contact Methods

-

Website URL

http://www.productionrecording.com

Profile Information

-

Location

Los Angeles

-

About

Production Mixer

-

Interested in Sound for Picture

Yes

Recent Profile Visitors

11,718 profile views

-

We have a housing built by Chinhda to hold two monitors. A sheet of clear Lexan provides protection for the screens from on-set hazards. There is a built-in speaker with volume control that may be used to monitor set activity during lighting. While the speaker is powered up, a meter tracks the voltage of the power supply. The speaker may be switched off for takes or simply reduced to no level to retain the power readout. On the left side there is a hinge to hold a clipboard for sides. It can fold against the monitors while moving or storing the cart and the tension of the hinge is adjustable. Please let me know if you are interested: David Waelder - davidwae@earthlink.net As with other items in the shop, all proceeds go to Chinhda's daughter, Kathy.

-

Still available

-

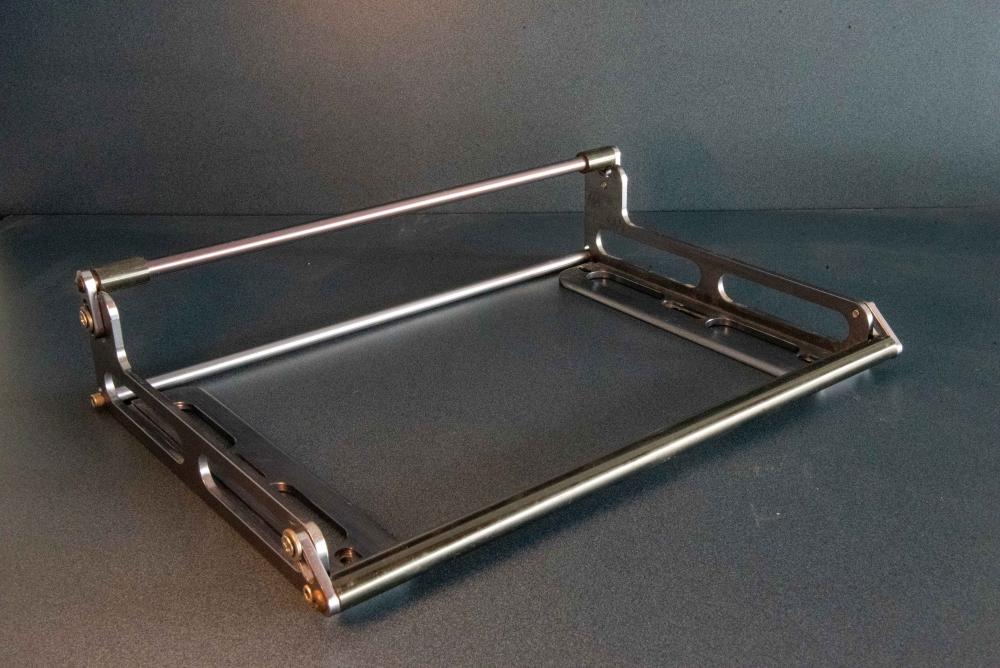

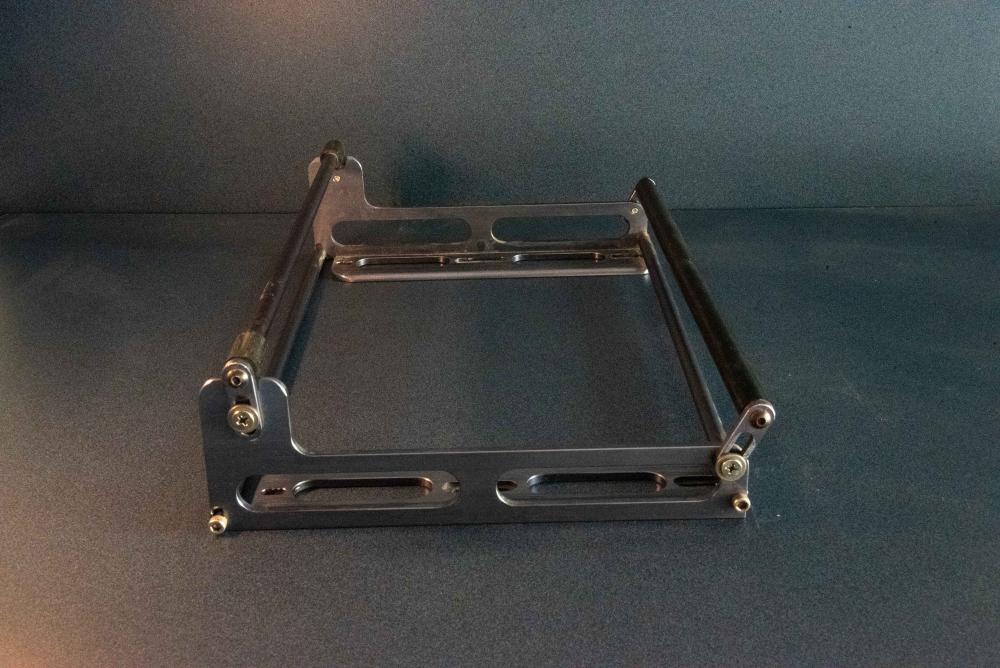

We have available a Chinhda bracket to hold a CL-9 mixing panel. Like all Chinhda brackets, this one securely holds the device without the need to drill any holes or make any modifications. The control surface drops into the bracket and adjustable bars clamp the mixer into place. It's made of anodized aluminum with Tygon tubing at points of contact. We originally charged about $350 for these brackets but the CL-9 is no longer a current product. We're thinking that $200 is reasonable under the circumstances. All funds received go to Chinhda's daughter, Kathy. Let me know if you are interested: David Waelder davidwae@earthlink.net

-

I used to cover Marc Gilmartin on double-up days. He had a cable hanging bracket attached to his cart. I don't know if this is the exact model he used but it's the idea: https://www.pacrad.com/middle-atlantic-equipment-accessories-claw.html Ordinarily, this is used to manage the pigtails that might otherwise clutter a sound studio. Marc used it to hang his lavalier microphones. He would either put a collar on the cable or attach a strip to make the slot more narrow. A cable that was particularly kinky might have a weight attached at the bottom to help stretch things out. He would routinely store lav cables this way and they tended to lie straight. Of course, he would pack up the lavs in the normal way when moving locations. David

-

There are many possible causes for the dropouts you are experiencing. I think your hunches are probably right but harnessing that insight to a solution is difficult. (But others may contribute good suggestions.) I can tell you that my experience has been that momentary hits are often easily corrected. That "pfftt" sound is loud but usually very brief. It does require work by the assistant editor to sliver the hits out but it can often be accomplished seamlessly and without excessive difficulty. Usually fixable, if that helps. Of course, occasions where the signal drops out for whole words is another magnitude of trouble. David

-

Some years back I was working a project where Gary Graver was the DP. I was setting up the espresso machine but the electricians blocked my access to power, telling me they were maxed out. I went over to give Gary the bad news that, due to limited power, I couldn't supply him with a cappuccino. Without missing a beat, Gary pointed to a light in the overhead grid and ordered that it be switched off to accommodate the coffee machine. A man with his priorities in order. David

-

Workflow for basic coverage of 2 actors talking.

David Waelder replied to HarryR2's topic in Workflow

John and Jeff - Thank you for your very kind words. Jim - (also Phillip) Your advice is spot on. I should have addressed that as well but I was focused on the particulars. David -

Workflow for basic coverage of 2 actors talking.

David Waelder replied to HarryR2's topic in Workflow

This is one of those questions that bedevil regulars on this site because there is no good answer. How to treat an interaction between actors is an artistic choice and also inextricably involved with the grammar of film. The question is analogous to asking how one would light the actors, who should be in shadow and who in light, etc. It all depends (to use the motto of a frequent contributor here). But, as I am not actively involved in production at this time and have no "dog in the fight" or reputation to protect, I'll try some general guidance. How much of the downstage actor is seen in each shot is a decision for the director and the D.P. but actors move and shuffle about even if you nail their shoes to the floor. (As they should) This means that even if the camera were almost directly behind the downstage actor, one might see an outline of the chin when he/she speaks. It's risky to count on replacing all the dialog of the downstage actor with lines recorded when it's their turn to be directly on camera. And, there is the issue of ad-libs that may mean that a line is never exactly repeated in the alternate angle. On a big show, e.g. episodic TV or a studio picture, there are at least three people on the sound crew. The dialog can be covered with two booms deployed by the primary Boom Operator and a Utility Sound Person or a dedicated Second Boom Op. Ideally each voice might then be recorded on a separate track so the audio of the "on camera" person is not cluttered with any noise or vocalizations from the downstage actor. If you don't have the personnel for two booms, you'll have to improvise. Sometimes, if the players are close together, a single Boom Operator can successfully record both voices, cueing back and forth. This can work very well if there are rehearsals or the Boom Op is well familiar with the dialog. Usually, a skilled Boom Op will hesitate to cue all the way back to the downstage actor and will swing the pole only partway and aim the microphone between the two speakers. This will usually yield a satisfactory recording of the downstage player and keep the microphone close enough to optimum position on the primary person to be quickly adjusted to best advantage. This advice is well known to most everyone here but, as you admit you are new to the game, I'll share this trick: actors will usually move their mouth slightly before they speak. So a Boom Op will usually keep eyes on the primary player even when adjusted back to get the downstage player and then, using this "tell," quickly adjust the microphone to capture the coming line. In this situation, getting an excellent recording of the person facing the camera is primary and one can risk losing a word or two from the other. (After all, one will probably get a better opportunity when that person is "on.") If distance or some other factor makes it difficult to record both players with your boom, satisfactory results can be achieved by putting a radio microphone on the downstage player. Remember that because the camera will primarily see only that person's back, there is no need to hide the microphone. It can be out in the open, free from being muffled by clothing. If the actors are stationary, one can sometimes rig a second boom pole on a C-stand using a boom support bracket made for that purpose. This is a bit risky because, as previously noted, actors can't be relied upon to hold a position. (And shouldn't have to) But, it can often work just fine and is a good option when there isn't enough equipment to use radio mikes and not enough people to boom everything. And, sometimes a Production Assistant can be drafted to simply crouch down and hold a microphone at waist height in front of the downstage player. In an over-the-shoulder shot it shouldn't be too difficult for the assistant to stay out of the picture. And, sometimes you just have to punt. David -

I've been using the Rycote Invision mounts. They've worked well for me. David

-

I have a Nagra Mezzo and it’s a terrific little recorder with stereo mikes built in. It’ll record 24-bit at 48khz, even at 96khz. It always sounds great (with the usual caveat about careful microphone placement) but I acknowledge that my use has been stenographic rather than audiophile. (I have other recorders I could use for that purpose.) However, I heard a recording of the church bells that Peter Weibel made at the Los Angeles Cathedral and it was outstanding, at least through headphones. I’ve never found the Mezzo to be fiddly but maybe some of the earlier handheld Nagras were. I checked the Nagra website and the Mezzo is still listed as current. David

-

Mark Pope is a sound guy working out of San Francisco. Per IMDB, he has only a few credits in sound, mostly shorts, but he has also pursued other occupations. Notably, he was one of the co-founders of Quark, Inc., the publisher of Quark XPress, a desktop publishing software that was very popular in the 80's and 90's. He's a very smart guy. He's also very politically outspoken on Facebook. His credits are a bit thin but I would have expected that he would know enough to assemble the gear without having to solicit a consultation to avoid a visual blunder. David He posted an inquiry regarding the design of a vertical cart on this site last February:

-

There is a switch in the sticks called a Hall switch. It's the Hall switch that signals the display to freeze for a few frames and then extinguish. The Hall switch has a shorter service life than the slate as a whole. It's an easy repair and not, as I recall, particularly expensive. But it does require a trip to a service facility. If possible, send your slate to Denecke in Santa Clarita, California. If that's difficult, call Charlie Parra and explain your circumstances. I expect he could send the necessary parts to a facility near you. David I see now that you are in New Zealand. That's a bit of a commute and a time differential that makes scheduling a phone call a challenge. You can email Denecke at: info@denecke.com David

-

If the situation is a controlled fire operated by a special effects technician, you should contact that person beforehand to introduce yourself and let him know that you'll be recording sound. You'll want to respectfully request a silencer for the gas line. A silencer is basically a length of gas pipe loosely stuffed with steel wool. It cuts down the hiss of the gas significantly. Don't assume that the EFX person will have that sort of gear on the truck. I've had EFX technicians tell me more than once that they have line silencing components back in their shop and would have brought them along if only someone had asked. David

-

Which is more versatile, Sennheiser MKH50 or MKH8060?

David Waelder replied to Nachosgrande's topic in Equipment

It's really an impossible choice; you would want to be prepared with at least one of each type on any assignment. But it's often possible to get excellent results with professional gear even using it outside its normal comfort zone. All The President's Men was recorded almost entirely with a Sennheiser 805/815 shotgun, even the interior scenes. Chris McLaughlin preferred the long shotgun and Jim Webb often deferred to his boom operator in microphone choice. David -

Ann Arbor, Mich. Mixer needed Sept 12

David Waelder replied to Ontariosound's topic in Work Available - Available for Work

Try Jeff Jones: ****** Road Ann Arbor, MI 48103 jeff@amazingaudio.com 734-761-1920 (landline) 734-216-7740 (cell) Jeff was a regular Chinhda client over a period of several years. I think much of his business has been for the auto industry. From many interactions,I believe he is operating at a high professional level. David