-

Posts

471 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Gallery

Store

Everything posted by Rachel Cameron

-

Fantastic customer service (new Endian)

Rachel Cameron replied to nevo's topic in General Discussion

Woa. What a situation to be in. I love LectroRM, and Freqfinder. Thanks James, +1 for getting nevo out of hot water like that. I'd be sweatin' it. And a mountain of thanks goes to all the industry innovators here who listen, consider, and attend to our professional requests, needs, and ideas at JWS. This is a suitably long list. -

Thanks Jeff, for the historical look at the inception of May Day.

-

Nagra Stories Sound-men won’t ever tell

Rachel Cameron replied to JBond's topic in Images of Interest

Thanks, I'm sure it would have cost me a bunch..and by the way, I love the pics you added. Well done! +1. So true, and welcome to the board, Richie. -

Nagra Stories Sound-men won’t ever tell

Rachel Cameron replied to JBond's topic in Images of Interest

So noir. Jealous that you have a phone booth. I've wanted one for years. At my film school, some kid dragged one to the sculpture area for some art project. After the critique, it stayed there for a year or two, sort of in the way..but too heavy to just move. It was a bit beat up, and needed a little work, but I could have had that thing just for asking. Lost opportunities. -

It's always a good idea to go with a local fixer, if the production can arrange it.

-

Beautiful pictures..still envious. How's the F8 holding up in the extreme temps?

-

I love this thread. Very nice Ryan. I love the Rockies. So much history is preserved out there. Nice going. What's the kit you're using?

-

Bronzed Grackles are in Florida by the boatload..and that green laser idea sounds intriguing. If I was a Grackle, I wouldn't like either I guess.. I'd love to know what they say.

-

How effective was this? Did it work?

-

Best soldering iron/gun for basic cable fixes by a novice?

Rachel Cameron replied to Dave's topic in Do It Yourself

+1. The flick method works good for me too. I always hit the iron cradle or a vice. But oftentimes, cleaning a pc board or overflowing solder cups is another issue. And I forgot to mention: the Soldapult is serviceable too. Unscrew it. Wipe it out. Coat everything inside with petroleum jelly. It's ready to go again. When I got the two I have, they were $12, so they went up some since then. -

Best soldering iron/gun for basic cable fixes by a novice?

Rachel Cameron replied to Dave's topic in Do It Yourself

These new Lithium Ion powered irons are really convenient. Both ends get hot enough to melt 63/37. All kidding aside. I've used many 110v powered irons. No matter which you settle on, I've found that best ones are the ones with a temperature control. Some have arbitrary numbers on the temp dial. Others go by Fahrenheit. A good desoldering pump is also a wonderfully handy tool to have. This Edsyn Soldapult is by far, the best I've used, because of its available volume, and the $20 pricetag. -

First thing I'd check is how the ECM-77b is supposed to be biased for the mic it's connected to. Edits: There also seems to be a phantom power requirement for the Sony. A quick look at the specs of the SMQV yields: Fixed 5 V at up to 5 mA; selectable 2 V or 4 V servo bias for any electret lavaliere. Interesting that it worked before. Until the real electro-brains arrive, I'd bet it's somewhere around those. : \

-

Boom Op Available for Work

Rachel Cameron replied to Don Coufal's topic in Work Available - Available for Work

It's nice to see you here Don, welcome from Florida! We've heard so many great things about you. The board just got better (again). -

You have too much fun Philip. Is that a pair of 81s on that Piano?

-

Unreal. Way to go Robert. One of my favs.

-

You have to post a picture for us now, at least.

-

That sounds like a good idea.

-

Dialogue Mumbling: BBC's Nazi Drama SS-GB

Rachel Cameron replied to VASI's topic in The Daily Journal

No mention of sound whatsoever. Pass me the hot poker. To me, this is just a bunch of pretentious fluff. It's the most annoying conversation I've had to sit through. Listen to them rationalize. Argh. Rant over. https://indiefilmhustle.com/mumblecore/ Edit: I stand corrected; It was named by a sound person. Either Eric Masunga or Randall Good, likely being a bit sarcastic and frustrated. -

About half of the time, the editor is standing somewhere nearby. Yep. If I can, I give them the cans (show them the report, which tracks, etc) and explain the mess we're currently in with that noisy __________ over there. Then I'll jump between the isos with the headphone selector and watch their expression. Makes me new friends. I just wish they were in higher places.

-

This is really an issue, worrying which track is going to end up in the mix. It's so difficult to make enough notes and recommendations to post on which is the track to use here or there. Worse, some of the jobs I do have 'not much post at all' or no RRM (at least I doubt it). At this point I would offer the DNS-2. But yeah Philip..rabbit hole for sure. All this has to be so carefully considered. Above all, I make sure to give post both tracks with bold warnings to please listen keenly to tracks 1 and 4 (dirty and DNS'd). Great idea, cstauffer. Please chime in, posties. Lets hear from anyone with opinions or experience here.

-

Thanks for such salient input guys. And Vin, the METCAL is darn impressive. Great advice on tinning the tip before power down. I've been wiping it off on the sponge, leaving it open to the local elements. My daily driver is the WES51, but I've had to repair it and tweak it a few times. I took it apart yesterday seeking a faulty connection. And besides help with tinning (the solder actually runs uphill by capillary action on the stranded stock), the flux in the tub makes a wonderful little bath for the tip. I melt a little pool of it, then sponge the tip shiny clean. It then drinks the Kester, and it's raring to go. I've the right solder, I just wondered if the flux I use is proper, or perhaps corrosive...or if it matters (EG: Ammonium Chloride or Zinc Chloride?). It seems to collect any slag and leave it in the tub, because over the years, I noted that it gets darker and darker..sometimes I look closely and notice slag particulate in it. That's exactly where I want it. Not in my joints. And +1 Sound Intuition.

-

Question for the solder brains: For what we do, is it prudent to use the little tub of flux? It's Zinc Chloride and recommended for copper, but they mention other applications, like sweating copper fittings. EG: Mitee Soldering Paste is one. The other is Dutch Boy Tinning Flux. Another is an old Radio Shack Rosin Solder Paste. That one's in a tube, and recommended for electronics. All three of them have made the solder flow so nicely, I never questioned it. The Tinning Flux mentions "for use with any Lead-Free Solder". But I use 63/37, eh...which has Lead. The joints I make are never less than pretty, shiny and succinct, but I wonder...

-

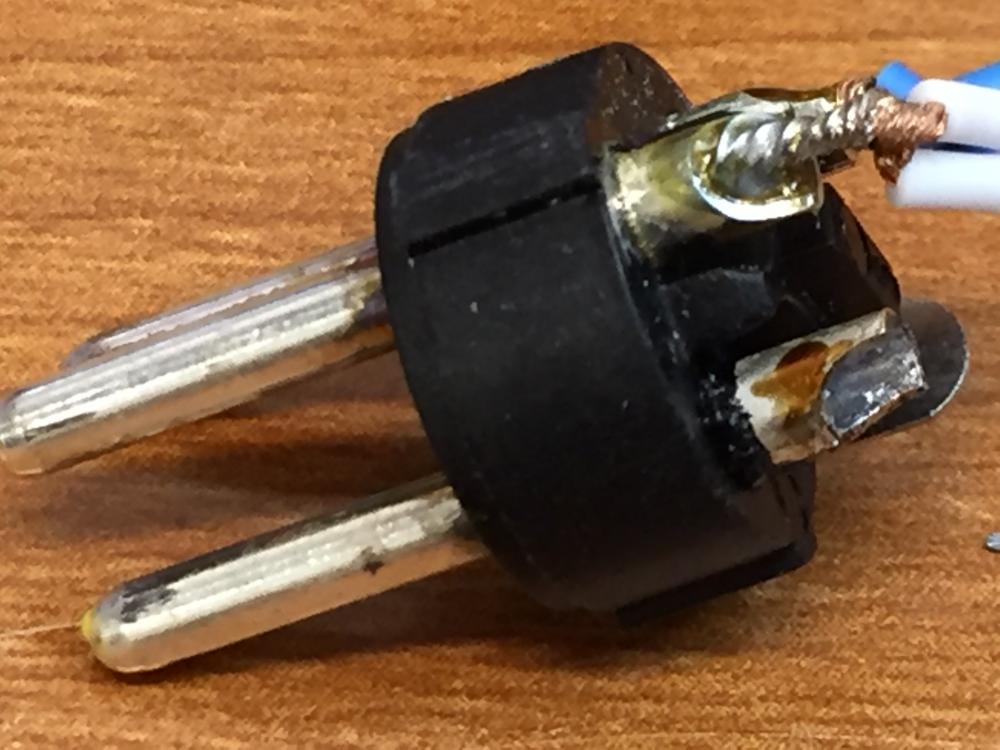

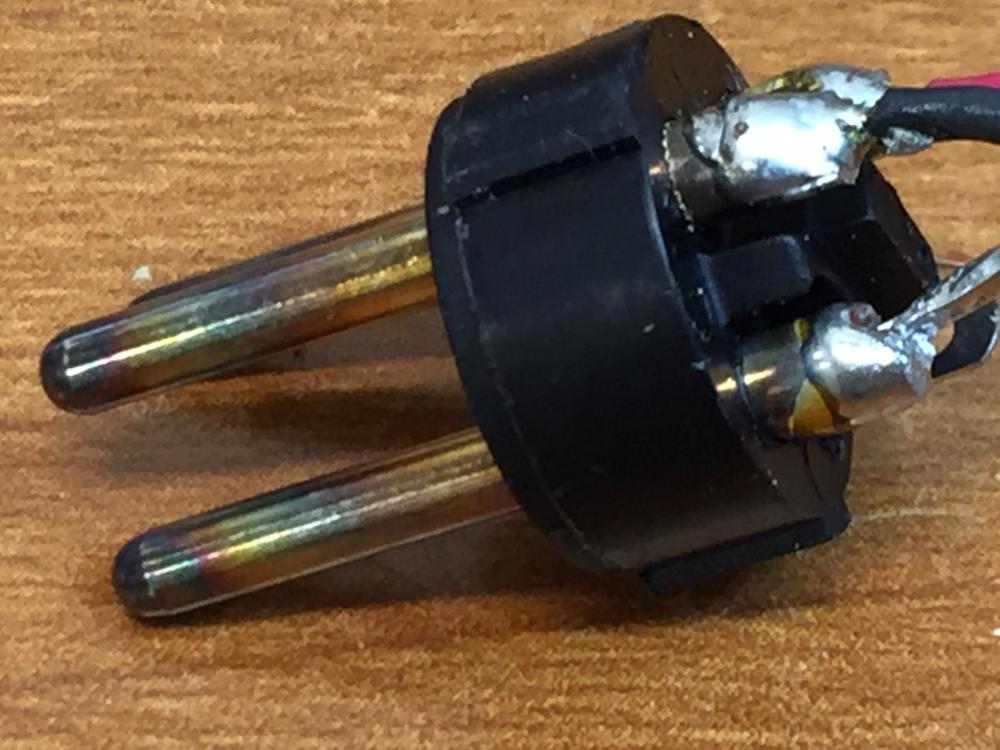

Okay. Running my soldering iron at 720 degrees (the usual setting), I only had to hold the iron to the cup approximately 20 seconds before it slipped pin 1 (pic 2). I checked it again on pin 2. Bubbling nylon coming out of the cup side of the insert at 23 seconds. But look at the first pic. Discolored somehow, yet no sign of melted nylon. Still a mystery. Before the test (pic 2), I was ready to increase the temperature to X (much higher), but there was no point in that. Still baffled, and we may never know.

-

Makes me want to run some heat tests on them.

-

That was my first thought. But the connector shows no sign of heat, otherwise. You'd figure, to discolor the pin would take such heat, that even a Neutrik connector might melt and slip the pins. It was crappy three conductor Mogami cable (with silk stranding in the copper) on the offending character (and a few others), Star Quad on the rest of them, but I can't see THAT as a cause. Baffling. There were fifteen or twenty XLR's (m and f) in this rack. Others show tarnish but not that 'rainbow' effect like extreme heat does to some metals. And the solder joints were all very nice, I.E. a pro installer made them up. This might even baffle a metallurgist. Go figure : /